Andes Coil Processors LLC, an independent steel coil toll processor with locations in Lewisville, Dallas, Grand Prairie and Ft. Worth Texas as well as Gary, IN.

Andes Midwest is located in the Great Lakes Industrial Complex at 201 Mississippi St. Gary, Indiana and currently occupies approximately 200,000 sft of space. It owns and operates 72” x 56,000#, 72” x 60,000#, 60” x 45,000# and 62” x 56,000” slitting lines, a 60” x 144” long CTL line, a 52” Embossing line and tractor/trailers for the Greater Chicagoland shipments.

For inquiries or further information about our operations, please contact our office at 219-886-0281 to speak to one of our inside sales representatives.

![]() Gary, IN

Gary, IN

201 Mississippi St.

Gary, IN 46402

Tel: 219.886.0281

Fax: 219.886.3337

Gary, IN Facility Machine Specifications

| 72" - | 73" - | 60" - | 62" - | CTL Line | |

|---|---|---|---|---|---|

| Coil O.D. | 78" max | 75" | 72" max | 73" max | 76" max |

| Coil O.D. Exit | 71" | 70" | 70.50" | 72" | |

| Coil I.D. | 20"/24" | 20"/24" | 20"/24" | 20"/24" | 16"/24" |

| Master Material Width | 73.25" | 72.00" | 62.00" | 61.00" | 60.00" x 144.00" max |

| Material Thickness | .020-.187 | .035-.312 | .012-.055 | .018-.125 | .016-.140 |

| Max Uncoiler Weight | 60,000 | 60,000 | 50,000 | 60,000 | 48,000 |

| Max Recoiler Weight | 50,000 | 60,000 | 46,000 | 45,000 | |

| Facility | 200,000 sft. climate controlled, StelPlan Toll Processing computer system with customer portal (Invex), (2) tractor/trailers, fork rear rampRail served - Servicing Carriers - NS and CN | ||||

| Rail Address | Northfolk Southern - Andes Coil Processors LLC201 Mississippi St. Gary, IN 46402Railroad Station: Burns Harbor, INServing Carrier: NS | Canadian National - Andes Coil Processors LLCGary, INTrack# GV33Serving Carrier: CN | |||

Above information subject to change due to gauge and size of master coils.

Cut-To-Length Line

Andes Coil-Midwest added a 60-inch cut-to-length line to the existing 72-inch and two 60-inch slitting lines, expanding the facility’s ability to process material to 4 lines running seven machine shifts with capabilities between .011- and .1875-inch thickness; up to 72-inch-wide master coils; and as narrow as .625-inches.

Incoming Capacity

-

- 55,000# Master Coils – All carbon, Aluminum, Stainless & PTD

- 60.00” Maximum Coil Width (+ 1 ½”) / 12.00” Minimum Coil Width, 76” Max OD

- 16” Minimum ID & 24” Maximum ID

Leveling Capabilities

-

- .056-.140 Gauge x 60” Wide Straightener

- .016-.100 Herr Voss Corrective Leveler

Production Capacity

-

- .056-.140 Gauge

- +/-.005 Width Tolerance (If slit prior / otherwise mill edge)

- +.015 /-.015 Length Tolerance

- 144” Maximum Length / 12” Minimum Length

Packaging Capacity

-

- 20,000# Maximum Stack weight / 24” Maximum Stack Ht. (Including Pallet)

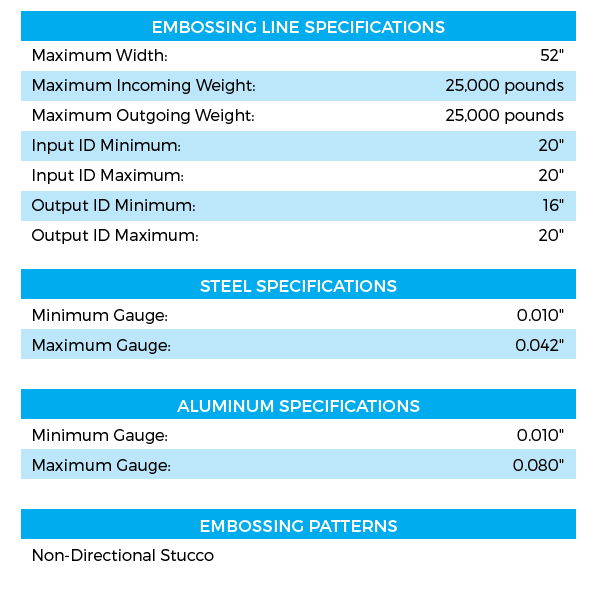

Embossing

The embossing procedure is a unique, metal-forming process producing raised and/or sunken designs into metal without changing the material thickness. Andes Coil Proccessors’ line provides the non-directional stucco pattern, producing a depth of up to .013 inch. This pattern services shelving products, industrial flooring, building products and many other products in related industries.

The line runs at a speed of 250 feet per minute plus, running coils between 5 inches in width up to 52 inches wide with gauge ranges between .010- and .045-inch thickness for steel products and .010- and .080-inch thickness for aluminum products. The maximum incoming and outgoing weight capacity is 25,000 pounds.